Production process of Decal Paper

- shenzhenchinaware

- Jun 12, 2020

- 3 min read

Updated: May 10, 2022

When clients want to put their designs on porcelain tableware, they can use the method of decals to achieve, it can be achieved by decal paper. At this time, clients will often ask us a few questions: What is decal paper? Is decal paper expensive? Therefore, this article answers the following topics:

1. What is decal paper

2. Main production process of decal paper

3. Factors affecting the price of decal paper

1. What is flower paper?

Decal paper, also known as water transfer decal, is a special kind of film. First, apply pouring water on the special film, then print the pattern on this special film, and then replace it with water to transfer it to the surface of the object (such as ceramic). Decal paper is mainly used to decorate irregular surfaces of ceramics, glass, sports equipment (helmets, rackets, etc.), metal, wood and other objects.

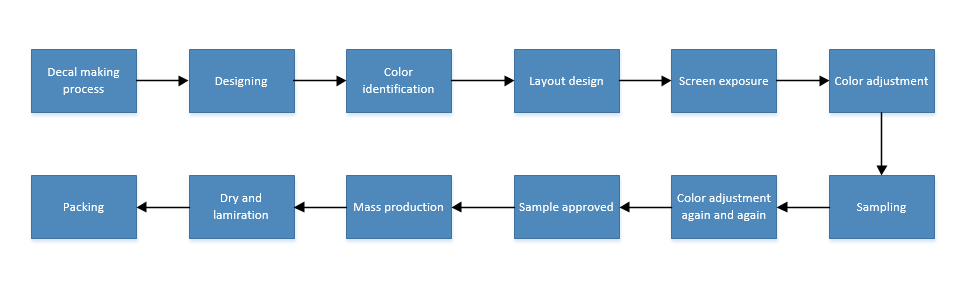

2. The main production process of decal paper

The production process of decal paper is mainly divided into five steps: color separation, screen board manufacturing, color adjustment, printing and inspection.

Color separation

When we receive the client's design, we will separate the design draft first. We will check whether the design draft is high enough, how many layers of color, and which colors can be overprinted.

Screen board manufacturing

Screen is the film that makes the design. Film is similar to camera negatives, which is the most expensive part of the whole decal printing. With the film of product pattern, we can make the screen board that needs to be printed.

Color adjustment

The pigment of ceramic is different from that of painting. It has a coarse particle sense and needs to be fired at high temperature to show color. For example, one kind of pigment is gray, which will turn red after being burned. Our employees know the characteristics of ceramic pigments very well. We will adjust the various basic colors of ceramic pigments according to a certain proportion to prepare specific colors of inks, in preparation for the next printing. Each time the ink is mixed, 500 pieces of paper can be printed, and the remaining ink cannot be stored for a long time. If the printing quantity is less than 500, the remaining ink can only be poured out.

Printing

We print the prepared ink on special film paper through screen boards. Generally, an ordinary design needs to pass through 3 different films and different screen boards, which are printed on the same film paper. If one of the prints is crooked, the whole film will be discarded. We have high technology in printing. The most times we have ever printed is 13 times.

Inspect

The special printed film paper is decal paper. After printing, our staff will check the design and original design carefully, every square millimeter will be checked. Only the decal paper that has not been misprinted can become a qualified product for the next step of baking on the ceramic.

3. Factors affecting the price of decal paper

Number of prints: the cost of each production of film, screen, machine start-up and workers need to be apportioned in each piece of paper, so when the number is more, the cost of apportionment will be less, and the price will be lower.

The complexity of printing: the more colors, the more films and screens are needed, the more difficult it is to make, and the higher the cost of paper. Gold pigment: gold can highlight the nobility of ceramic products. The golden color on ceramic plates is printed with real gold ground into oil. So, the cost of gold is much higher than that of ordinary pigments.

Special pigments: when making children's tableware, EU countries require high standards, because all pigments must be free of lead and cadmium, as result, the cost of pigments will also be 30% - 50% higher.

4. Conclusion

In Shenzhen Chinaware, you don't need to worry about the final effect, because we have rich experience in the processing of decal paper and have high requirements for quality. All you have to do is provide the design and tell us the details you require, then leave all the work to us, and we will give you a satisfactory result in the shortest time.

If you have a tableware project, or if you are looking for a reliable tableware manufacturer, please feel free to contact us!

Comments